The workshop is small and with the minimum industrial machinery so that the work is cost efficient, productive and the most important: Competitive.

We are not interested in mass production, we prefer personal direct contact with our customers, this way we can bring their ideas and design to the real word for their own enjoyment.

Whether your project is hundreds of feet of custom estate fencing or a simple fire screen or even a small repair, we will satisfy all of your metalworking needs. We also offer you our long experience to be capable of taking a project from conception to completion.

As we already said, we use machinery that help us to be more cost efficient, this way we can: cut, bend, pull, curve, heat, forge, join, solder, rivet, pierce, polish, clean, paint....

Detailing a bit more, we have: guillotine shears for metal sheet cutting, swivel bending machine for straight bending this metal sheets, round bending machine for making round curves in metal sheets, hand bending devices for bending different profiles, metal saws, column drill, hand and stationary grinding machines, spot welding, MIG, TIG and plasma cutter, polishing machine to give a shiny finish to our works, multiple hand-held electrical and manual tools… and the more “vintage” blacksmith tools for forging and working metal like in the ancient times.

Each work is unique and different as each customer preferences or needs are unique and different, each object that we create is something yours and I always try to apply what my father teach me, master builder of the old school.

Nobody likes working, it you try to do it right, you will no need to do it twice.

Work in what you like most, working hours will become shorter.

Put the same interest in a big work that in a small repair.

A work made wrong, as soon as it leaves the shop is out or your sight. But the customer will see it daily, and will remember you… for a bad work.

Let people to say that one of your works is expensive, but never that is made.

Work to live, do not live to work.

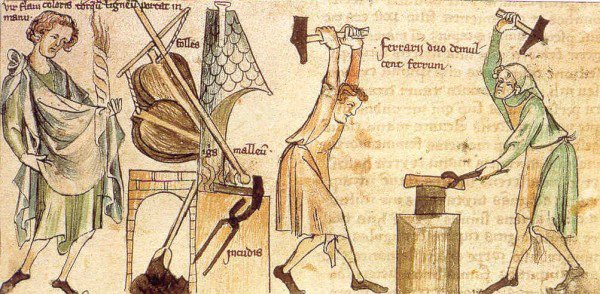

The techniques of work, are not very different to the ones used in the Middle Age, but for the ease of the use of machines.

PFor example, in the past they joined the pieces by means of metal rivets heated in the forge and upset with a hummer until they remained joined. Nowadays we joint the pieces by welding them with different techniques: arch welding, spot welding, TIG, MIG…

The more ancient and traditional technique is the forge: with the hammer, anvil and pliers the ancient masters were able to build any object. Today we “cheat” a little, as we can cut, transform and join with a plasma welding machine.

The material we use the most is, logically, the iron. It comes in normalized sizes and dimensions. In 6 meter bars, in different shapes: square, round, rectangular. In different thickness and width. Tubes of black iron (get rusted) or galvanized (antioxidant treatment) square or rectangular also in a big variety of measures.

Stainless steel, brass, copper and other materials. To create pieces of furniture and decorative objects, we love mixing iron, in its different finishing (polished, corten, painted, blackened, burnished...), with other materials (stone, wood, marble, glass, ancient objects....). We also like, mixing the different appearances and textures of the multiple finishing of the material to end up with a piece of furniture that can be classical, modern, industrial or functional.